Allocation

When a process involves several products, you have to assign how much of the impact each product is responsible for. Typical examples of such processes are co-generation of heat and power (multi-output) or a landfill (multi-input). These allocation problems can be dealt with using two different strategies; partitioning or system expansion.

Partitioning

There are three allocation by partitioning methods in openLCA:

-

Physical allocation: partitioning based on the physical relationships between the products in terms of, for example, mass.

-

Causal allocation: partitioning based on assumptions or former research on the relative impact of different products.

-

Economic allocation: partitioning based on the economic (cost or revenue) relationships between products. Consequently, an economic property in terms of cost/revenue has to be added for this to be applicable.

Moreover, we also provide the following technical solutions:

-

As defined in processes: this option will perform allocation according to the method used in each individual process along the supply chain.

-

None: if none is selected, no allocation will be applied, even for multifunctional processes. Hence, each product of a process gets the entire impacts of this process and its supply chain.

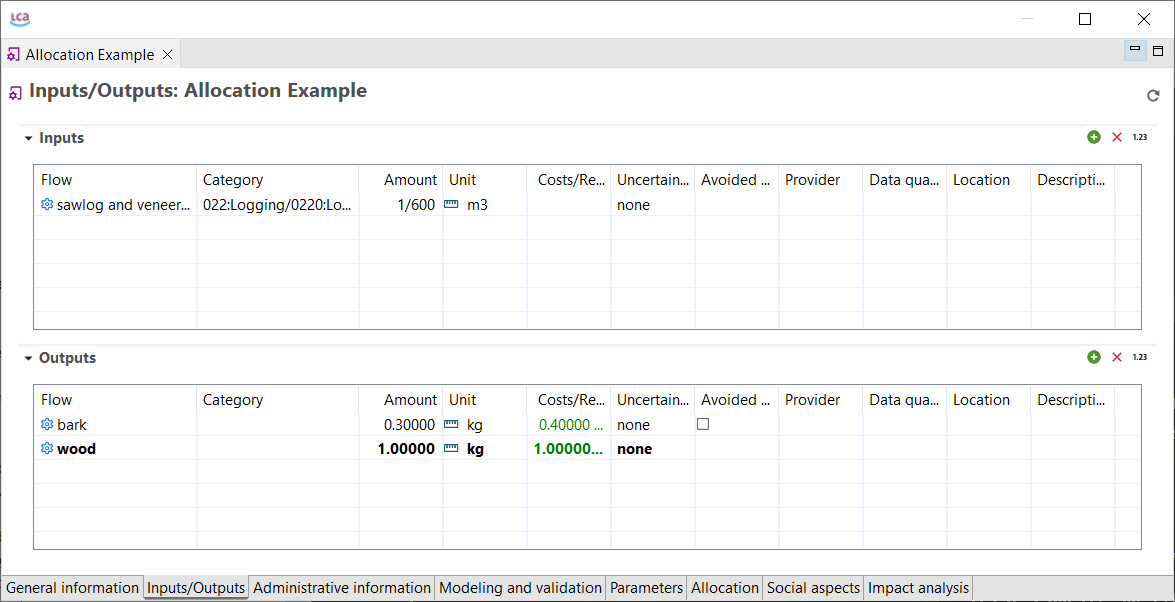

Below is an example illustrating how the three different methods are applied in openLCA. In this example, 1.0 kg of wood and 0.3 kg of bark are produced from 1.0 kg of saw log (measured as solid wood under bark).

Inputs and Outputs for our example, note that economic properties have been added

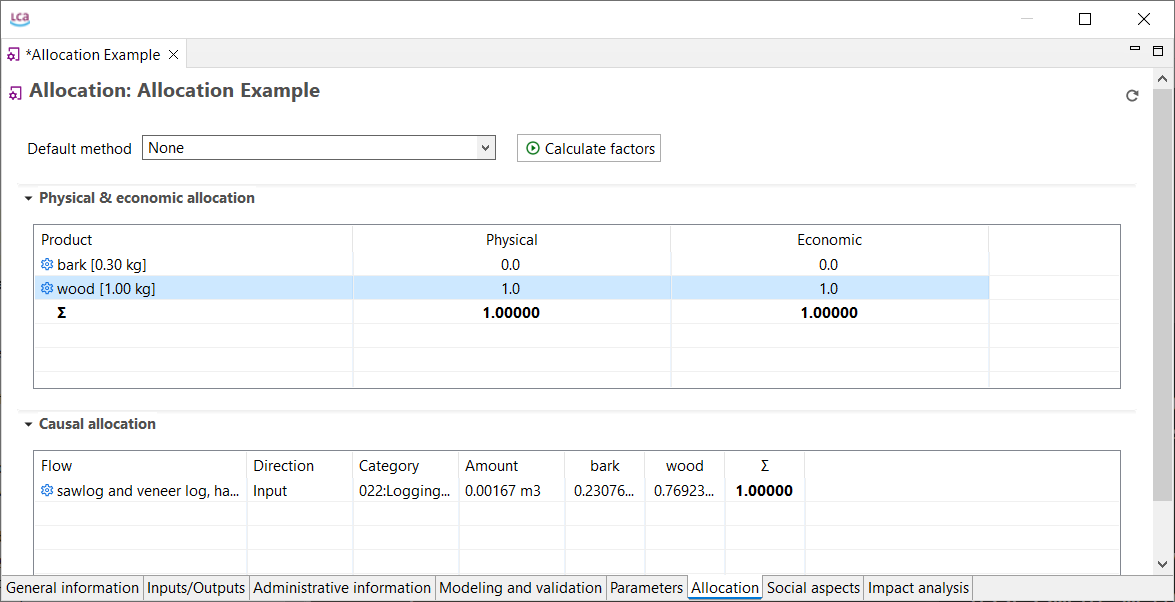

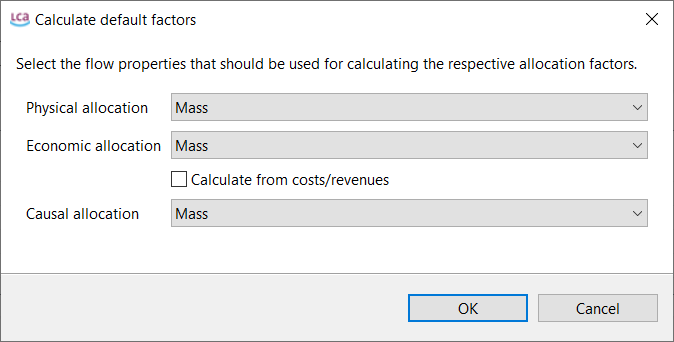

The allocation factors for physical, causal and economic allocation can be viewed/altered in the "Allocation" tab of a process. Select the "Calculate factors" button and the software will automatically calculate the values for the three allocation methods.

The "Allocation" tab with the "Calculate factors" button

Calculate factors

-

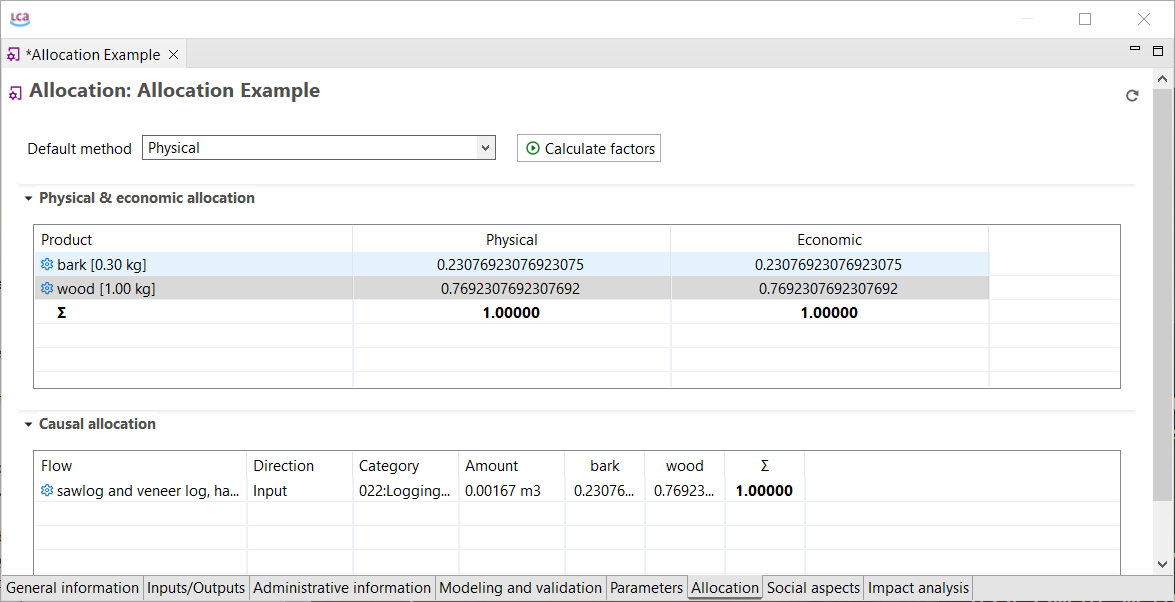

The physical allocation factors are calculated based on the ratio between the products (wood and bark) physical unit. Since the output of wood and bark is 1.0 kg and 0.3 kg respectively, the allocation factors become 0.77 and 0.23.

-

For causal allocation an assumed ratio can be inserted. In this example, we assume that the wood is responsible for 60% of the impacts, whereas bark is responsible for 40%.

-

In the case of economic allocation, we assume a revenue of 1.0$/kg for wood and 0.4$/kg for bark.

Important: openLCA does not automatically update the allocation factors prior calculation of a product system. Hence, it always uses the last saved allocation factors. So, if you work with allocation in your study, make sure that the allocation factors are in the most recent state prior to creating a product system. However, it is possible to use Parameters and Formulas in allocation factors, which are updated during the calculation of the respective product system.

Calculated allocation factors. Causal allocation has to be inserted manually, else it will by default get the physical allocation factors.

Note: For the automated calculation of the allocation factors, the main product and the by-products need to have the same flow property. But openLCA will tell you if this is not the case. However, if you manually fill in the allocation factors (physical, economic or causal) or formulas, openLCA will refer to those.

Note: When a currency is unavailable, a new currency can be created under "Currencies" under the "Background data" in the Navigation panel. A conversion factor can be added according to whatever reference currency is set.

Allocation for Recycling

Be reminded that also recycling processes are multi-output processes as they treat waste and produce recycled material hence they require allocation. It is necessary to use allocation to distribute the impacts according to the linked process. A short example on how to model recycling in openLCA is displayed below:

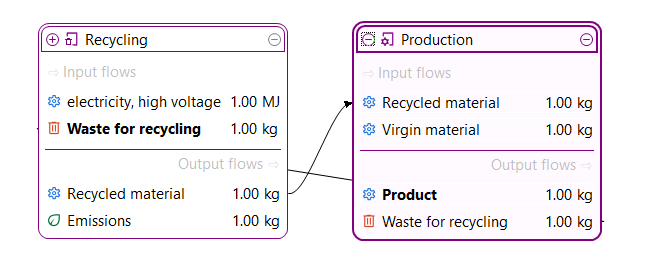

The model graph for a recycling scenario

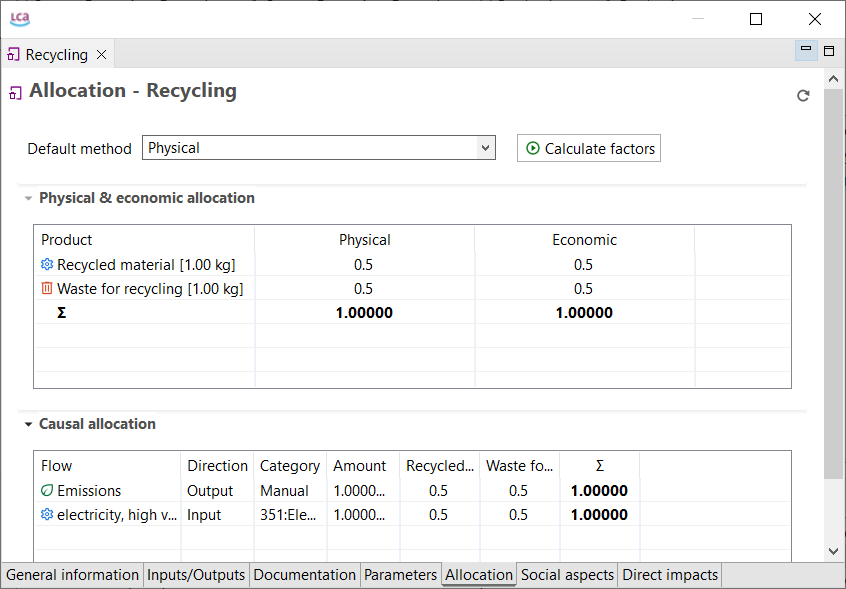

As the recycling process is a multi-output process allocation is needed! Here, physical allocation was applied.

Note: Here we allocated 50% of the impacts to the recyclate and the waste. This is only one option. However, if you are not modeling a closed-loop scenario this can be a relevant detail you should consider.

System Expansion

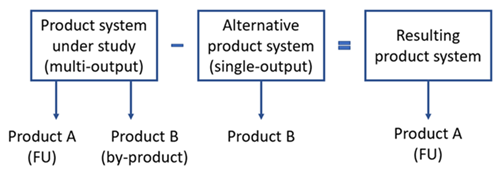

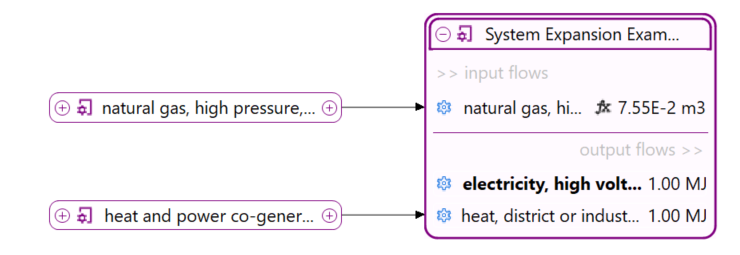

Another way to address multi-output product systems is through System Expansion. In system expansion, the inventory associated with the production of a by-product is subtracted from the total inventory of the multi-output product system. This “avoided impact” is calculated based on an additional, single-output product system that “expands” the system boundaries.

According to ISO 14044, system expansion should be the preferred approach for handling multi-output processes, as it avoids allocation by accounting for the impacts that would be generated if an alternative process supplied the by-product.

Expanding the system boundaries to subtract the impact of a by-product from the product system

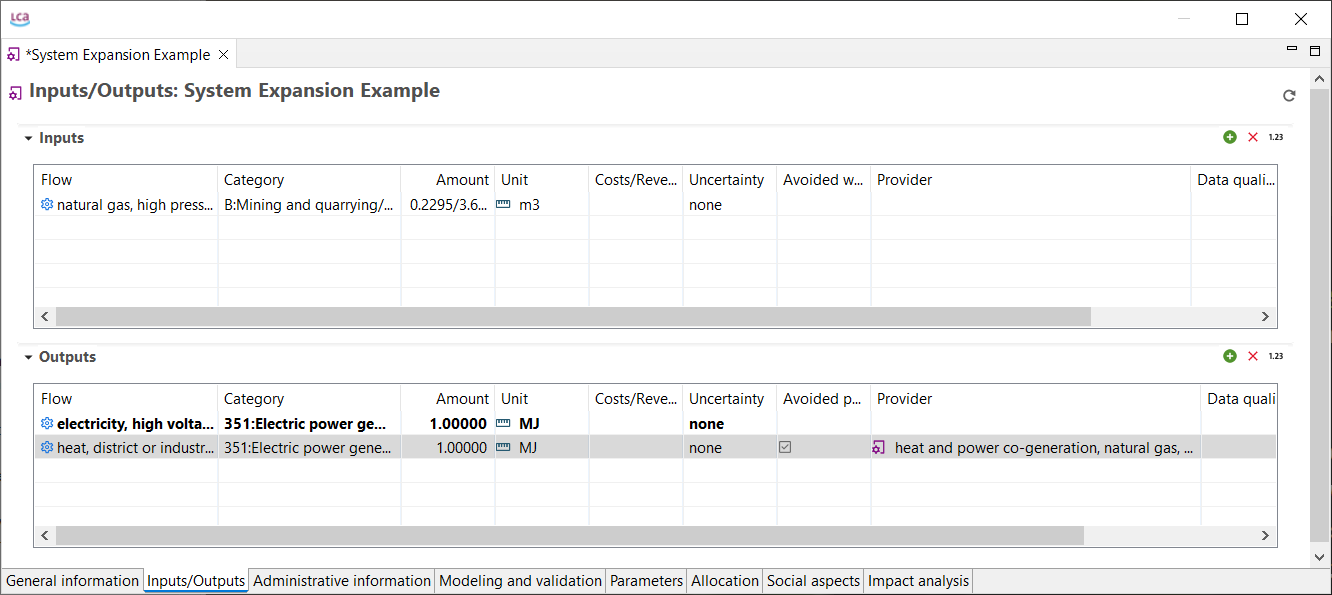

For example, if a process produces electricity and heat (such as in a co-generation setup), and you want to isolate the impacts of producing the electricity, the heat can be treated as an avoided product. This means that the environmental impact of producing the same amount of heat via another process (e.g., “Heat, gas heating”) is subtracted from the total impacts of the co-generation system. Effectively, the modeled system is "credited" for offsetting that external heat production.

In openLCA, system expansion can be implemented by checking the “Avoided product” box for the by-product as seen below:

Avoided product check box highlighted in the Inputs/Outputs tab

It is important that a process providing the avoided product flow exists in the database. When creating the Product system, this provider will appear in the Model graph as a supplier on the output side of the original process.

The model graph showing heat as an avoided product, with a respective provider for the output

Note: In the model graph, avoided flows are displayed in italics, making it easier to distinguish them from regular flows, especially in more complex systems.